Find out which crusher is right for you!

Optimizing Material Processing with High-Performance Lump Breakers. Built for Strength, Precision, and Reliability.

Contact us for a free evaluation

Industry-leading lump Breaker equipment company located in wayne, nJ

For over four decades, JERSEY CRUSHER, headquartered in Wayne, NJ, has been a leading manufacturer of lump breakers. We provide a range of products designed to break up items from various industries, including chemical, pharmaceutical, fertilizer, spice, mineral, sugars, drug, grain, food, foundries, and other commodities that tend to lump or agglomerate in storage or from the production process.

Increase Profits

Increase Productivity

All Application Requirements

LUMPBUSTERS®: Precision Crushing for Efficient Size Reduction

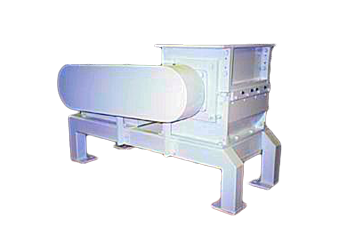

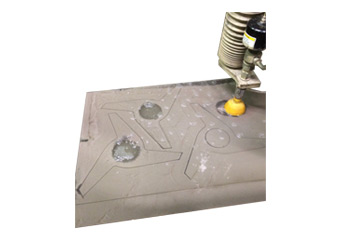

Our exclusive LUMPBUSTERS® are designed for breaking up friable substances which do not require heavy pounding of hammers, balls, or pin mills. Size reduction screens or breaker bars are integrated into our design to size processed products to our customers’ specifications. Screens can be sized with hole diameters ranging from ⅛” to 2”, with additional customizable options also available.

As a lump breaker manufacturer headquartered in Wayne, NJ, our business is built on providing your company with efficient and effective crushing methods saving you time and money in the process. We provide proven solutions for all types of commodities, including materials that are abrasive, products requiring sanitary handling, and bottle crushing machines designed to handle the needs of the recycling industry.

Customized Crushing Solutions to Maximize Profit and Minimize Costs

Whether you are a top-of-the-line processing company or a small manufacturing company just starting out, JERSEY CRUSHER, a leading lump breaker manufacturer in Wayne, NJ, can help increase your profits and reduce costs in a number of ways. Our particle size reduction equipment, made exclusively in Wayne, NJ, can be shipped directly to your location. We ship across the country to states including New York, Illinois, California, Pennsylvania, South Carolina, Florida, and Texas.

Maximize Efficiency and Profitability with Expertly Designed Lump Breakers

By incorporating lump breakers equipment from our company in Wayne, NJ, your business will be able to increase system productivity and flow rate while also decreasing downtime and improving profitability. Our size-reduction equipment is an excellent tool for corporations across varying industries. As a premier bottle crushing company and chemical crusher company located in Wayne, NJ, our engineers design our machinery to cater to a multitude of applications helping manufacturers overcome key issues in their processing systems.

Lower Construction Costs & Inefficiencies with JERSEY CRUSHER's Crushing Equipment

With decades of experience as a lump breaker equipment company in Wayne, NJ, JERSEY CRUSHER has worked at perfecting its technology and has consistently strived for high-quality manufacturing. Our equipment is fully mobile and can be moved to different locations at your plant or a construction site. This facilitates on-site recycling, allowing you to avoid disposal and transportation costs simultaneously.

Maximize Efficiency and Profitability with Expertly Designed Lump Breakers

Our experience as a lump breaker company operating in Wayne, NJ, has enabled us to build machinery capable of crushing both large and small aggregate volumes. If needed, our staff can provide technical guidance on implementing our size reduction equipment into your system processes. We’re firmly focused on providing our customers with solutions that work for their specific industry. In addition to providing technical expertise, our crushing company, based in Wayne, NJ, also accepts product samples customers ship to us in order to design custom solutions for your field of work.

As a highly-rated lump breaker manufacturer in Wayne, NJ, JERSEY CRUSHER can evaluate sample products to determine a system or machine that best meets your construction needs. Given our equipment’s unparalleled track record for durability and reliability, your business will benefit from implementing our particle size reduction equipment made in Wayne, NJ, into your processes, ensuring maximum profitability.

Our products are available to ship nationally and are currently used in states like Texas, Florida, Pennsylvania, California, Illinois, New York, and elsewhere. Don’t settle for less when it comes to acquiring high-quality crushing equipment for your industry. Trust the leading crushing company in Wayne, NJ, with your production needs.

Our crushing equipment is regarded as top-of-the-line in our field. Machinery is available in 316 stainless steel, 304 stainless steel, carbon steel, and other abrasion-resistant materials. As a bottle-crushing and chemical crusher company in Wayne, NJ, we also specialize in machinery designed explicitly for those industries, ensuring product size reduction meets the requirements of your business. As a lump breaker manufacturer based in Wayne, NJ, we strive to design and manufacture customizable solutions that can be used in countless applications, which also include the food and pharmaceutical fields.

Improve Internal Processes and Increase productivity with a leading crusher manufacturer based in wayne, nJ

JERSEY CRUSHER is setting the standard as a lump breaker company in Wayne, NJ, providing real solutions to product processing. Our team of designers is constantly updating equipment configurations to provide your company with the best particle size reduction equipment. In Wayne, NJ, our company offers turnkey solutions for businesses looking to improve profitability by utilizing state-of-the-art crushing technology.

Modern Crushing Solutions for faster recycling & Cost Reduction

Working in tandem with the construction industry, our team understands the complexities involved in product removal and disposal. Yet, by implementing our crushing equipment, you can speed up the recycling process, allowing for fast implementation of resources to different applications. As the pace of varied industries continues to accelerate, conventional crushing equipment can no longer satisfy their demands, lowering production speeds and bogging down the equipment with caked-up pieces or lumps of material.

JERSEY CRUSHER, the leading lump breaker manufacturer in Wayne, NJ, provides modern solutions for the modern era to customers nationwide.

Equipped with skilled engineers driven towards excellence in their field, our team can help your business find the options it needs to sustain itself and reduce costs.

Whether you’re in greenfield development, supplemental crushing, developmental crushing, or the elimination of any resource burden, our LUMPBUSTERS® and other products can offer highquality, easy-to-implement solutions for your crushing requirements. Our products are manufactured in Wayne, NJ, and spare parts are always made available. Contact JERSEY CRUSHER today and let us help your business eliminate internal redundancies and increase profit margins with our high-quality crushing equipment solutions.

Efficient crushing solutions for a stronger, more profitable industry

Enhancing efficiency across industries with precision crushing technology

Explore the features of our lump breaker machines and other eqiupment

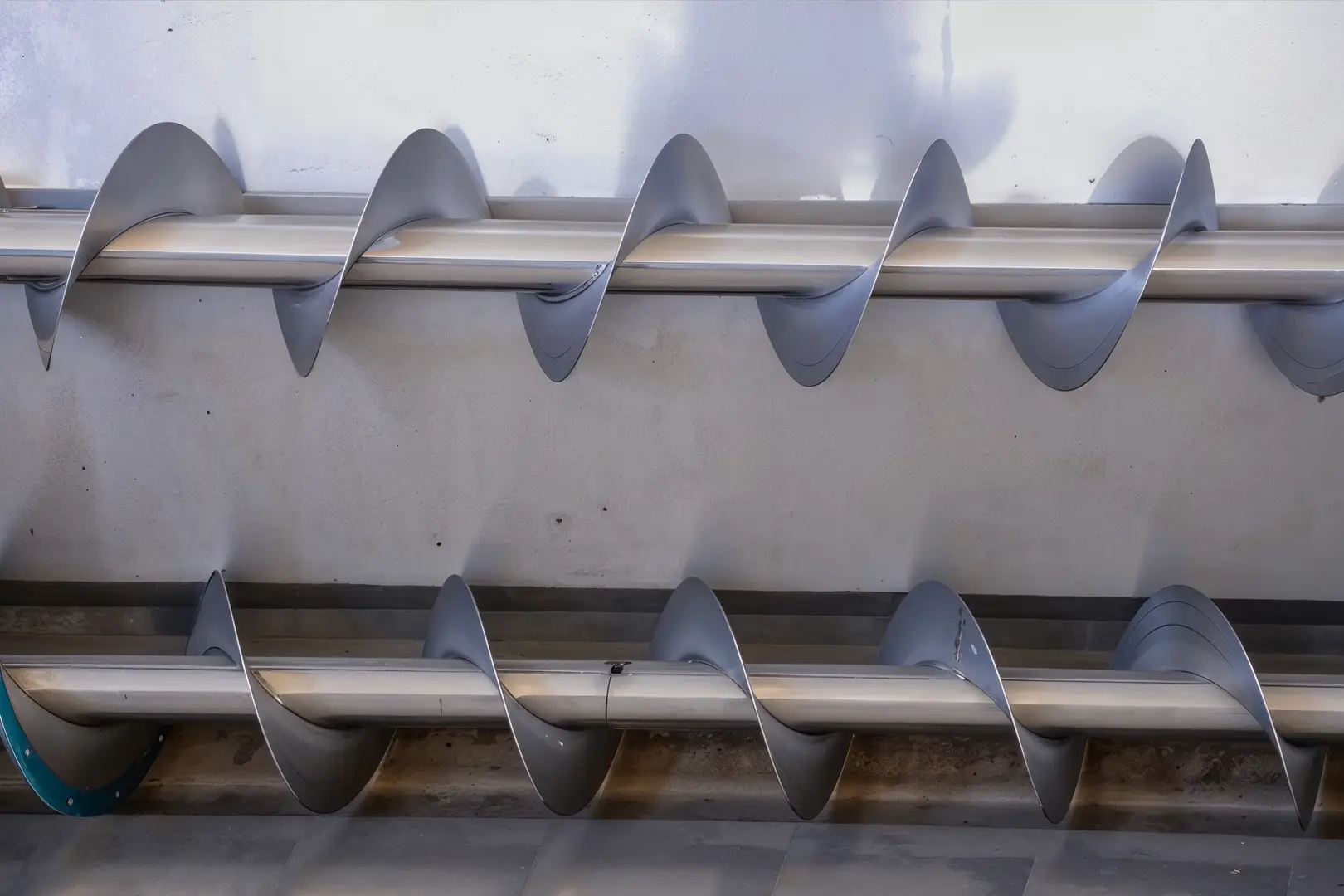

JERSEY CRUSHER offers an impressive range of industrial machinery, including Lump Busters®, Lump Abradors, Particle-izers, Screw Conveyors, Feeders & Systems, and more.

Main Features

Construction

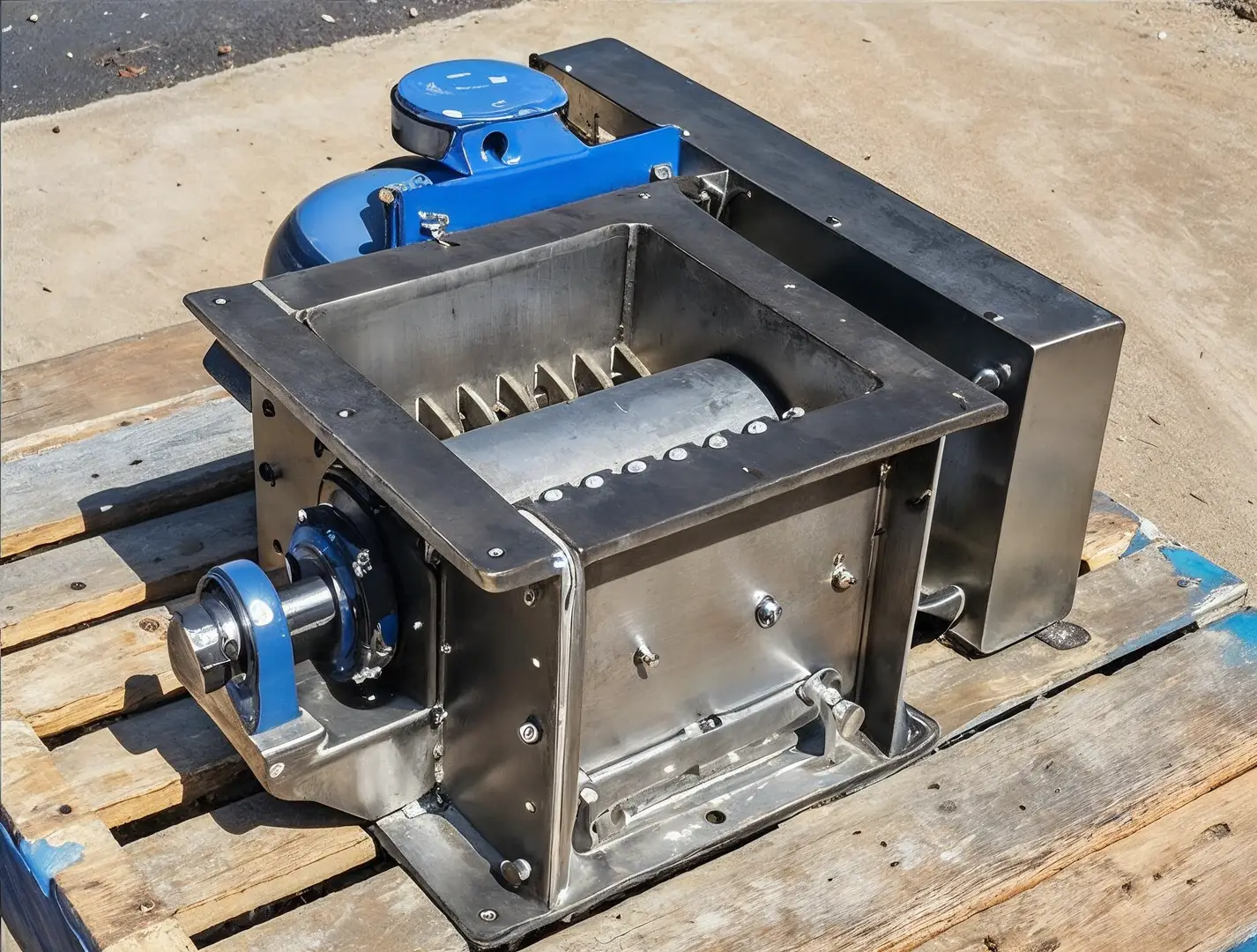

One of the key standard features of these machines is their construction. The carbon steel units are painted with blue enamel for durability, while food-grade white epoxy and high-temperature inorganic carbon/zinc primer are optional interior finishes. For those seeking a more premium finish, standard stainless steel units are supplied with a mill finish, with only the contact parts considered. These units also boast baseplates and guards in stainless steel.Dual Rotor Crushers

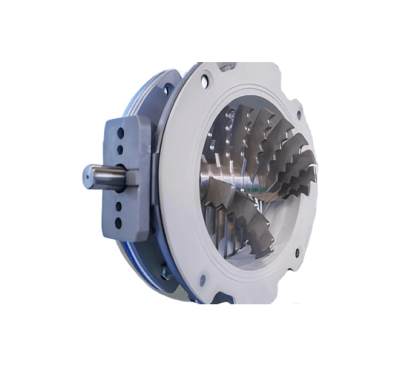

Dual rotor crushers require a breaker bar or screen to ensure optimal operation. We also offer optional infeed hoppers with safety baffles and support stands for convenience. On powder applications, venting and/or dust collection should be considered, indicating our attention to detail and commitment to safety.Air purge shaft seal

Another notable feature is the inclusion of air purge shaft seals in all units, which ensures the longevity and efficiency of the machine.Standard Mortor

Particle crushers come equipped with a 230/460/3/60 TEFC 1800 rpm motor with a belt or direct drives with gear reduction for severe applications.