Are you searching for lump busters with steel hoppers to thoroughly break apart materials or waste and then collect them? Or does your business require 20 HP motor lump busters to meet your facility’s specifications? Whatever sort of lump busters you require to run your company smoothly, you can find the machinery you need at JERSEY CRUSHER.

Read More

Operating from New Jersey, we’re proud to have served numerous industries since 1982 with our continually advancing LUMPBUSTER® machinery. Varying businesses, both big and small, have improved their operations across the country by incorporating JERSEY CRUSHER technology into their facilities. Some of the many locations we support include:

● New Jersey

● New York

● Illinois

● California

● Pennsylvania

● Florida

● Texas

● South Carolina

● And more

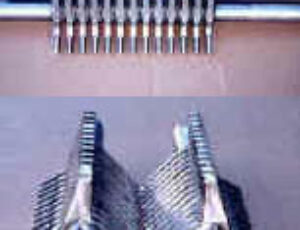

Sanitary Stainless Steel LUMPBUSTERS®

There are a number of advantages to utilizing sanitary stainless steel lump busters beyond their renowned durability. Not only is stainless steel highly resilient to flames and other extreme temperatures, but it resists corrosion and is easy to clean. Some of JERSEY CRUSHER’s stainless steel machinery includes:

● Model 1515

● Model 2020

● Model 2028

● Model 3636

● Model 1212

● Model 2424

Alternatively, several of our models are made as carbon steel lump busters. Compared to their stainless steel counterparts, carbon steel lump busters have increased durability at the cost of being prone to rust. Whatever crusher material suits your business the best, you can find it at JERSEY CRUSHER!

Capable Chemical Lump Breakers

Reducing material volume is the primary purpose of steel lump breakers from Florida to New York. This doesn’t just include solid particles but liquids as well. Our chemical lump breakers can reduce the size of designated materials for further processing, easier storage, or whatever other purposes your business requires.

Food Reduction and Powder Lump Breakers

Consistency is crucial to maintaining a uniform size. This fact holds true in both the pharmaceutical industry and food companies, meaning JERSEY CRUSHER’s capable steel lump breakers serve a vital role in both fields. The LUMPBUSTERS® that our engineers develop work to benefit the operations of all corners of the food industry, including businesses that produce raw sugar. To ensure that no lumps remain in their products, companies in California, Texas, Illinois, South Carolina, Pennsylvania, and other states can utilize our powerful powder lump breakers in their facilities.

Lump Breakers Designed for Mineral Processes

Our lump breakers are powerful tools designed to handle the toughest mineral processing tasks, ensuring a seamless workflow that translates into high operational efficiency and increased profitability.

Our LUMPBUSTERS® are built with innovative design and cutting-edge technology, capable of breaking down even the most resilient mineral ores into manageable sizes.

They offer superior performance in crushing and reducing deliberately compacted materials and minerals, enabling optimal extraction of valuable components. The strength of our LUMPBUSTERS® lies in their robust construction and the precision engineering that goes into every unit.

With JERSEY CRUSHER’s LUMPBUSTERS®, you can take control of your mineral size reduction processes with confidence, knowing that you have the power to handle any challenge that comes your way. Additional benefits include:

● Efficiency: Lump breakers speed up the processing of large lumps or chunks of hard minerals into manageable sizes, increasing overall plant efficiency.

● Uniform Particle Size: They ensure a consistent particle size, which is essential for many downstream processes in the mineral industry.

● Reduced Downtime: The use of lump breakers can reduce plant downtime by preventing blockages and jams in other equipment caused by oversized material.

● Cost Savings: By improving process efficiency and reducing downtime, lump breakers can help reduce operational costs.

● Improved Material Handling: Broken down materials are easier to handle, transport, and store.

Pharmaceutical Industry-Based Lump Breakers

Our LUMPBUSTERS® are engineered to reduce plant downtime and increase processing speed, thereby improving overall operational efficiency. They exhibit high torque at low RPMs, effectively breaking up larger agglomerates for easier downstream handling.

LUMPBUSTERS® also helps reduce dust and debris during mixing processes, a benefit highlighted by many of our clients. Other materials are known for generating excessive dust, but our products ensure a cleaner work environment and minimize potential contamination risks in pharmaceutical production.

With the rise of sustainability concerns in industries, our LUMPBUSTERS® also contribute to waste reduction. Minimal-waste lump breakers can reduce deliberately compacted materials without tons of excess spent energy, improving downstream processes. If you want an efficient and effective solution, look to JERSEY CRUSHER.

Lump Breakers and Crushers for Sugar, Salt, Cereals, and More

JERSEY CRUSHER’s LUMPBUSTERS® stands as a beacon of power and strength in the realm of sugar, salt, and cereal processing. These machines are the epitome of efficiency, designed to reduce plant downtime and increase processing speed.

Our size reduction equipment is adept at breaking down material lumps and clumps that form during the production or transportation process of friable lumps and materials. This is particularly beneficial for industries dealing with sugar, salt, and cereals, where moisture can cause dry bulk materials to clump together.

LUMPBUSTERS® also enhances the handling and transport of raw materials. They break down agglomerated materials, facilitating easier shipping and storage. This ensures the smooth feeding of the production process with de-agglomerated dry materials, thereby optimizing operational flow. Another significant benefit of our lump breaker machinery is its ability to reduce dust and debris during mixing processes. If you’re looking for a cleaner and healthier work environment while saving time on clean-up and disposal operations, we have the right solution for those in the sugar, salt, and similar industries. Get efficient lump-breaking action for all material types from JERSEY CRUSHER.

Consult JERSEY CRUSHER Today for Your Lump Breaker Needs

Whether your facility needs 20 HP motor lump busters, lump busters with steel hoppers, or both, reach out to JERSEY CRUSHER! We also offer evaluation services, so if you want to know if one of our machines is just right for your business, you can send us some of your products for a thorough test.

Our advanced and dependable machinery has served countless companies since our founding. JERSEY CRUSHER’s engineers continue to make improvements and advancements to our breakers, and we will continue to support businesses like yours. To learn more information about our evaluations, spare parts, and other products and lump breaker services, please feel free to contact us for more details.