Lump Abradors in Wayne, NJ

JERSEY CRUSHER is your premier source for state-of-the-art lump abradors in Wayne, NJ. We’re dedicated to providing you with the very best particle reduction machinery, with a focus on efficiency, durability, and exceptional customer service.

Our lump abradors are engineered to crush large particles into smaller, manageable sizes. These robust machines are designed for high-capacity and continuous operation, setting the standard in the industry for performance and reliability. Whether it’s for food processing, construction, or industrial applications, our lump crushers are the top choice when it comes to reducing large solids.

At JERSEY CRUSHER, we understand that every application is unique and requires a specific solution. We counter that by providing a selection of lump abradors, each designed to meet varying operational requirements. Contact us today to learn more about our lump abradors and the rest of our lump-crushing machines in Wayne, NJ.

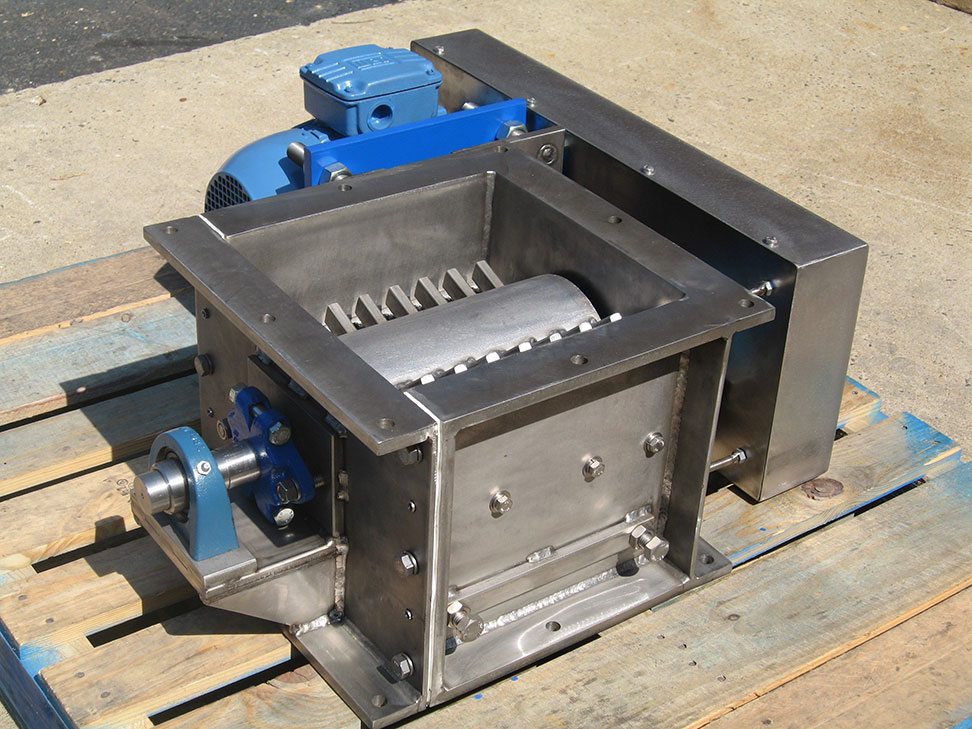

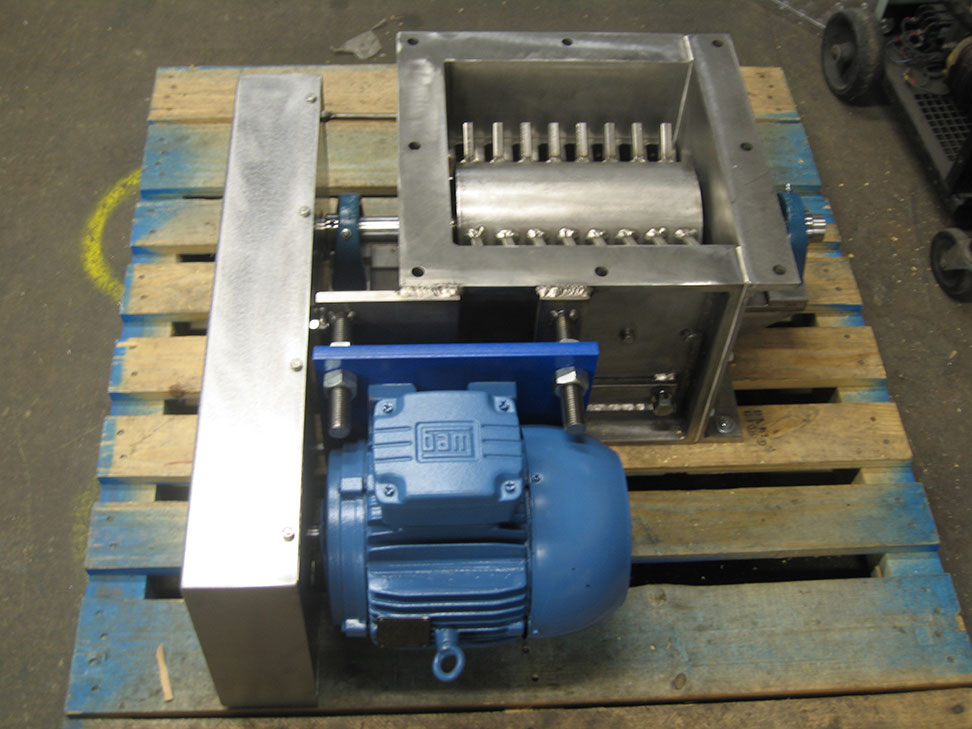

Our Lump Abradors

Lump Abradors have a single large diameter rotor, evenly spaced impacting fingers, and fixed combs on the side wall. The Blades intermesh with the breaker bars, acting as a series of crushing hammers. Particles smaller than the breaker bar slots continue through the machine while larger particles are trapped within the impact area, which continues to be crushed until small enough to flow through.

Unique Features:

- Large diameter drum which forces material to cutter edge

- Reversible motor

- Sanitary style units offer quick and easy change of screens and combs without the use of tools while the unit remains in-line

- Capacities from 60 to 1600 cubic feet per hour

- Rotor speeds 300-1800 RPM

Material of Construction:

- Carbon Steel

- Stainless Steel

- Sanitary Stainless Steel

- Other Alloys

What Are Lump Abradors Designed for?

Our lump abradors are specifically designed with versatility and adaptability at the forefront. These powerful machines serve a wide range of products and industries, providing efficient and precise crushing solutions for large particulate materials.

Our lump abradors excel in the food industry, transforming items like chocolate powder, crackers, cookies, and pasta noodles into smaller particles for easy processing and packaging. They also play a critical role in the chemical industry, where they break down large chunks of chemicals, urea prills, and sugar lumps to ensure uniformity and improve the efficiency of chemical reactions.

They also effectively handle thermoplastic resins, reducing them to the desired size for easier molding or further processing. Similarly, they help pigment manufacturers achieve consistent color quality by breaking down various pigments into uniform particles.

Wondering if our lump abradors are right for you? Explore the industries we serve below:

● ABS Resin

● Aluminum Sheet

● Aluminum Graphite

● Break Compounds

● Calcium Chloride

● Camera Bodies

● CD Discs

● Cellulose

● Cereal Products

● Cocoa

● Coke/Graphite/ Pitch

● Credit Cards

● Cosmetics

● Currency Distribution

● Dye Lumps Epoxy Resin

● Filter Press Cake

● Foam Glass

● Food Products

● Graphite Compounds

● Gum Resin

● Hard Candy Recovery

● Kraft paper

● Lexan

● Lumber

● Nylon

● Paper

● Pharmaceuticals

● Photographic Film

● Pigments

● Plastic Bottles

● Plastic Mold Purging

● Plastic Sprues/Runners

● Polyethylene

● Polypropylene

● Reject Product Distribution

● Resin

● Rubber

● Scrap Foam

● Sodium Chloride

● Spices

● Sugar Lumps

● Thermoplastic Sheet

● Tobacco Leaves & Stems

● Toner

● Video Cassette Tapes

Get Your Hands on Industry Leading Lump Abradors From JERSEY CRUSHER Today

JERSEY CRUSHER is your trusted partner for high-performing lump abradors in Wayne, NJ. Our machines are designed with precision and built for endurance, ensuring that you get the most out of your investment. With our lump abradors, you can transform large particles into smaller ones effortlessly, improving your overall production efficiency and product quality. We serve organizations across the following states:

● New Jersey

● New York

● Illinois

● California

● Pennsylvania

● Florida

● Texas

● South Carolina

● And more

We invite you to explore our other innovative products, like our particle-izers and LUMPBUSTER® — each designed with the same commitment to quality and performance. Reach out to us today and let our team help you discover the right solution for your needs.