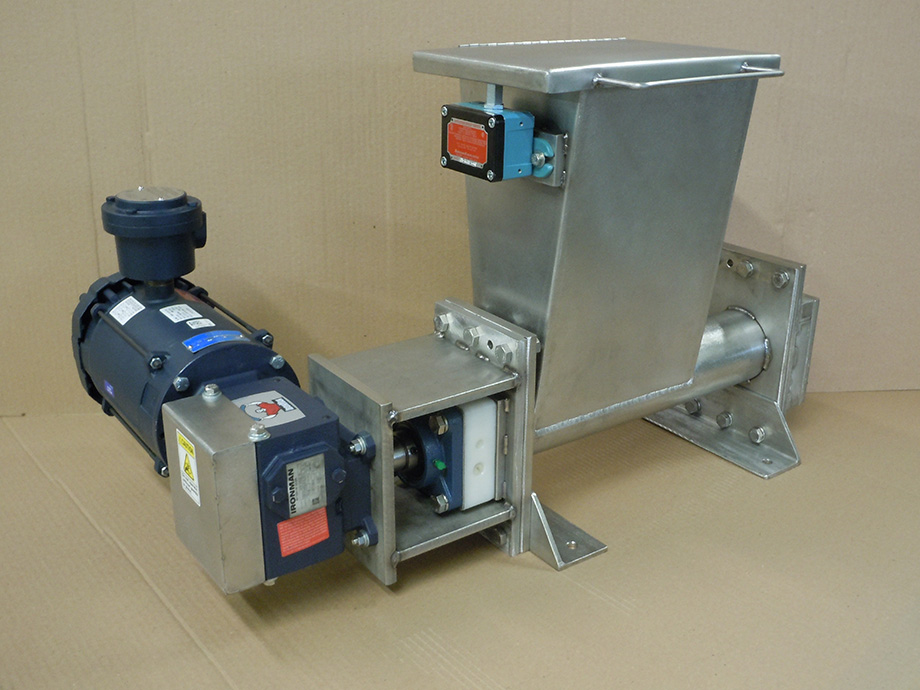

JERSEY CRUSHER offers a full line of Volumetric Feeders for applications in the pharmaceutical, food, and dry solid material industries. All units are designed for easy use and cleaning. We offer stainless steel and sanitary stainless steel construction in our volumetric feeders for durability and long life. Our durability and reliability are unmatched in the industry and show our commitment to leading the way for chemical, pharmaceutical, and other industries nationwide.

Explore our selection of volumetric feeders and systems today and find the ideal products for your needs. Contact us today to learn more.

Our Volumetric Feeders Supply Plenty of Industries

Looking for volumetric feeders with reliable feeding and speed? Trust JERSEY CRUSHER. We have been providing top-quality industrial equipment for years to come, and our volumetric feeders are no exception. From particle-izers to screw conveyors and our industry-leading LUMPBUSTERS®, we have tools that have redefined bulk material handling and size reduction in more ways than one.

For accurate, reliable, and consistent feeding of dry solid materials in various industries, contact us today. We serve the following:

- ABS Resin

- Aluminum Sheet

- Aluminum Graphite

- Break Compounds

- Calcium Chloride

- Camera Bodies

- CD Discs

- Cellulose

- Cereal Products

- Cocoa

- Coke/Graphite/ Pitch

- Plastic Mold Purging

- Plastic Sprues/Runners

- Polyethylene

- Polypropylene

- Reject Product Distribution

- Credit Cards

- Cosmetics

- Currency Distribution

- Dye Lumps Epoxy Resin

- Filter Press Cake

- Foam Glass

- Food Products

- Graphite Compounds

- Gum Resin

- Resin

- Rubber

- Scrap Foam

- Sodium Chloride

- Spices

- Sugar Lumps

- Thermoplastic Sheet

- Hard Candy Recovery

- Kraft paper

- Lexan

- Lumber

- Nylon

- Paper

- Pharmaceuticals

- Photographic Film

- Pigments

- Plastic Bottles

- Tobacco Leaves & Stems

- Toner

- Video Cassette Tapes

Why a Volumetric Feeder?

When handling material, the last thing you want to do is leave your processes up to chance. Every aspect needs quality tools, especially when feeding high volumes of material to machinery. With a volumetric feeder from JERSEY CRUSHER, you can get controlled, accurate, and reliable material feeding solutions with one simple product. We ensure a consistent flow of materials to the next stage of your process, enhancing efficiency and productivity.

Benefits of Volumetric Feeders:

- Precision: Volumetric feeders allow for precise control over the rate at which materials are fed into a process. This accuracy is crucial in many industries where the volume of material can impact product quality or operational efficiency.

- Consistency: Our volumetric feeders deliver a steady, uniform flow of material, eliminating the risks of over- or under-feeding that can disrupt your operations.

- Versatility: Volumetric feeders can handle a wide range of materials, from powders to granules, making them suitable for various applications.

- Efficiency: By automating the material feeding process, volumetric feeders reduce manual labor, increase throughput, and enhance overall operational efficiency.

We Offer a Wide Selection of Volumetric Feeders

JERSEY CRUSHER understands that different industries have unique needs. That’s why we offer a varied selection of volumetric feeders, each designed to address specific material handling challenges. Whether you need a feeder for light powders, heavy granules, or anything in between, we have a solution that fits your needs.

Our product range includes small-capacity feeders for laboratories and research facilities, medium-capacity feeders for small to medium-scale production lines, and high-capacity feeders for large-scale industrial operations. Each model boasts robust construction, user-friendly operation, and easy maintenance, promising long-term reliability and performance.

Volumetric Feeders for Pharmaceutical, Food Processing, and Other Industries

Volumetric feeders play a crucial role in various industries, and JERSEY CRUSHER is proud to serve a wide range of sectors.

In the pharmaceutical industry, precision is paramount. Our volumetric feeders provide accurate and consistent material feeding, delivering precise formulation and strict compliance with regulatory standards that define your business and its continued growth.

In food processing, our feeders facilitate the efficient handling and mixing of ingredients. They ensure consistent recipe formulation, contributing to product quality and customer satisfaction for years to come. We’ll keep your products safe, healthy, and reliable and provide the peace of mind and trust you need in an industry partner.

Beyond these, our fantastic volumetric feeders also cater to industries like chemical processing, plastics manufacturing, and more, providing exceptional feed rates and other benefits. No matter your industry, you can count on JERSEY CRUSHER‘s volumetric feeders for efficient and precise material handling.

Look to JERSEY CRUSHER for the Industry Leading Volumetric Feeders You Deserve

Choosing the right volumetric feeder can make a huge difference in your operations. That’s why JERSEY CRUSHER is right for you.

Trust us to provide the industry-leading volumetric feeders you deserve. With our products, you can expect improved efficiency, enhanced productivity, and a smoother operational process. Contact us today to learn more.

We Provide Volumetric Feeders All Across the Nation

JERSEY CRUSHER delivers our volumetric feeders to clients nationwide. Our Wayne, NJ headquarters serves as the nexus for our extensive distribution network, reaching industries across Pennsylvania, Virginia, Ohio, New Jersey, Florida, and New York. You’ll find our volumetric feeding solutions powering production lines and enhancing material flow in diverse sectors throughout these states. Our commitment to excellence in volumetric and gravimetric feeding systems extends beyond borders, offering reliable dosing systems wherever your operations are based.

Answering Your Volumetric Feeder Questions

What Applications Are Our Volumetric Feeders Used for?

Volumetric feeders find extensive use across various industries, playing a big role in material handling and dosing applications. You’ll see these systems in action in food processing, where precise ingredient proportioning is vital. In the pharmaceutical sector, volumetric feeders contribute to accurate drug formulation. Chemical industries rely on them for consistent blending of raw materials. Plastics manufacturing benefits from volumetric feeding for adding colorants or additives. These versatile machines also excel in cement production, waste treatment, and even in specialized fields like nutraceuticals. The key advantage lies in their ability to maintain a steady flow rate, which is crucial for maintaining product quality and process efficiency in your operations.

How to Select Accurate Volumetric Feeder Types?

Selecting the right volumetric feeder type hinges on several factors specific to your application.

Consider the material properties you’re working with — is it free-flowing or cohesive? This determines whether a screw feeder, belt feeder, or vibratory feeder might be more suitable. Assess your required feed rate and the level of accuracy needed for your process. Evaluate the feeder’s compatibility with your existing production line and its ease of cleaning and maintenance. Don’t overlook the importance of material testing — it’s often beneficial to run trials with your specific materials to determine the best feeder configuration.

What’s the Difference Between Gravimetric Feeders and Volumetric Feeders?

The key distinction between gravimetric feeders and volumetric feeders lies in their method of material measurement and control. Volumetric feeders operate based on volume, dispensing a set amount of material over time without real-time weight feedback. They’re simpler in design and typically more cost-effective for applications where slight variations in material density aren’t important.

Gravimetric feeders, on the other hand, incorporate weight-sensing technology. They continuously monitor and adjust the feed rate based on the actual weight of material dispensed, offering higher accuracy and consistency. This makes gravimetric feeding systems particularly valuable in processes where precise material ratios are crucial or when dealing with materials that have varying densities. Your choice between the two depends on your specific accuracy requirements and process constraints