LUMPBUSTERS® and similar machinery are integral to the processes of many businesses. However, there are certain circumstances where components in size reduction machines grow old or break. If any vital components are broken, it can halt your company’s workflow and reduce productivity. No business wants to put its operations on hold, so if you ever need spare parts for lump busters, there’s a company you can rely on for support.

Should your JERSEY CRUSHER machinery require maintenance, whether in the form of repairs or spare parts for lump busters, facilities in most states can receive assistance from our team, including:

- California

- Florida

- Illinois

- New Jersey

- New York

- Pennsylvania

- Texas

- South Carolina

- And more

Spare Parts for Lump Breaker Repairs and More

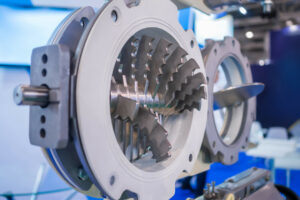

As there is a wide range of lump breaker machinery, it is only natural that there are a large number of corresponding components. No two types of lump buster systems have the exact same parts, meaning that spare parts for lump buster replacements aren’t a one-size-fits-all situation; even machinery of the same type can come in varying sizes. However, no matter what machinery your business utilizes, we have the right spare parts for the lump breaker repairs you need.

JERSEY CRUSHER designs and creates many different varieties of breakers for use in countless industries. This means that we also offer lump crusher spare parts for a myriad of different machines. From LUMPBUSTERS® and abradors to feeding systems and particle-izers, we have lump crusher spare parts for all types of machinery your business utilizes.

Spare Parts for Any Industry

Need spare parts for lump crushing machines? Look to JERSEY CRUSHER! Not only are we home to some of the finest size reduction and material handling products, but we also have spare OEM parts to keep your tools running smoothly and handling the needs of any industry. These industries include:

- ABS Resin

- Aluminum Sheet

- Aluminum Graphite

- Break Compounds

- Calcium Chloride

- Camera Bodies

- CD Discs

- Cellulose

- Cereal Products

- Cocoa

- Coke/Graphite/ Pitch

- Credit Cards

- Cosmetics

- Currency Distribution

- Dye Lumps Epoxy Resin

- Filter Press Cake

- Foam Glass

- Food Products

- Graphite Compounds

- Gum Resin

- Hard Candy Recovery

- Kraft paper

- Lexan

- Lumber

- Nylon

- Paper

- Pharmaceuticals

- Photographic Film

- Pigments

- Plastic Bottles

- Plastic Mold Purging

- Plastic Sprues/Runners

- Polyethylene

- Polypropylene

- Reject Product Distribution

- Resin

- Rubber

- Scrap Foam

- Sodium Chloride

- Spices

- Sugar Lumps

- Thermoplastic Sheet

- Tobacco Leaves & Stems

- Toner

- Video Cassette Tapes

Affordable Replacement Parts for Lump Crushers

Size reduction machinery can be costly, so it is only natural that replacement parts for lump crushers can be similarly expensive. However, it does not have to be that way. At JERSEY CRUSHER, we’ll help you find the right lump buster parts replacement without putting a hole in your business’s budget! Whether you’re a large Illinois company that has been in the industry for years or a smaller Florida company that’s just getting started, we’ll help you save money and get your operation back on track.

Replacement Parts for Common Problems With Lump Breaker Machines

The efficiency of your operations depends on the reliability of your equipment. Lump breaker machines, while robust and durable, can sometimes face issues that require part replacement. We’re here to ensure that these replacements don’t become a roadblock in your productivity.

We solve the most common problems with lump breaker machines, including:

- Frequent Jamming: This is a common issue often caused by worn-out blades or teeth. Our high-quality replacement blades are designed to handle even the toughest materials, reducing the chances of jamming and improving overall machine performance.

- Reduced Efficiency: Over time, wear and tear can reduce machine efficiency. Replacing key components like bearings, belts, and motors can bring your machine back to peak performance. At JERSEY CRUSHER, we provide all these parts, ensuring they meet the highest quality and durability standards.

- Irregular Particle Size: If your lump breaker isn’t producing the consistent particle size it once did, it might be due to worn-out screens or grates. We offer a range of replacement screens and grates in various sizes to suit your specific needs.

- Excessive Noise or Vibration: These issues can indicate a problem with the machine’s bearings or shafts. We provide top-grade replacement bearings and shafts designed to minimize noise and vibration while maximizing machine lifespan.

The parts we provide include, but are not limited to:

- Blades or Teeth

- Bearings

- Belts

- Motors

- Screens or Grates

- Shafts

Looking for more options? We’re always looking to address your needs in a timely and efficient manner. Broach any requests with our team, and we’ll happily bring you the products you deserve to ensure efficient lump breaking action for the lifespan of your investment. Contact us today to learn more about our spare parts for lump breakers and other size-reduction equipment.

Replacement Parts for Chemical, Food Reduction, and Mineral Processes

From corrosive chemical substances, edible products in the food industry, or the handling of hard rocks and ores common in mineral processes, JERSEY CRUSHER leads the way with replacement parts for the largest industries in the world.

From heat-resistant materials to corrosion-resistant coatings, our parts ensure your machines can handle whatever chemicals are thrown at them.

In an industry where hygiene is paramount, our replacement parts also meet the highest standards of cleanliness and food safety. We provide blades, screens, and other components made from food-grade materials, ensuring your lump breakers continue to provide safe, efficient operation.

The mineral industry demands durability above all else. Our replacement parts, including robust blades and wear-resistant screens, are designed to handle the hard, abrasive materials commonly found in this industry.

Reach Out to JERSEY CRUSHER for Lump Crusher Spare Parts

For many years, the engineers at JERSEY CRUSHER have worked hard to improve our buster technology so that businesses from Pennsylvania, Texas, California, New York, and other states can improve the operations of their systems. Whether you want to acquire lump buster part replacements to repair current equipment or purchase an entirely new machine, you can rely on JERSEY CRUSHER to deliver spare parts for lump busters and other products of the highest quality.

Additionally, if you are unsure if a product you intend to crush fits our LUMPBUSTER® models or want to learn what crusher functions best with your materials, you can send us a sample to find the answer. Our headquarters is located in New Jersey, and we’re happy to answer all of your questions regarding our spare parts for lump busters and other particle-reducing machinery services.