Screening

Industrial Screening Equipment for Material Separation

Your entire operation hinges on the quality of your raw materials. A single bad batch or an inconsistent mix can cause massive headaches, from production slowdowns to subpar final products. Getting the material separation right from the start isn’t just a step in the process; it’s the foundation for everything that follows. When your material stream is clean and properly sized, your entire facility runs better.

That’s where JERSEY CRUSHER comes in. We supply the heavy-duty industrial screening equipment that gives you complete control over your materials. You get the consistency you need for a higher quality output and a more efficient workflow.

Read More

Getting the Right Particle Size Every Time

You know how important consistency is in manufacturing. A recipe in a food plant or a compound in a chemical facility requires precise measurements and particle sizes for the process to work. When particles are too large or too small, it throws everything off. This is about more than just looks; it’s about performance and safety.

Our screening equipment gives you the power to classify and sort your materials with a high degree of accuracy. By separating particles by size, you create a uniform solid stream that flows predictably through the rest of your system. This improves your overall productivity and gives you a final product you can count on, batch after batch.

Protecting Your Downstream Equipment

Think about what a single oversized rock, piece of metal, or chunk of wood can do to your mixers, grinders, or packaging machinery. One unexpected object in your material stream can cause a catastrophic failure, leading to expensive repairs and even costlier downtime. It’s a constant risk in any industrial setting, especially in construction or mineral processing.

Our screening machines act as the first line of defense. They are built to catch and remove these oversized and unwanted materials before they ever have a chance to reach your more delicate downstream equipment. It saves you money, time, and the frustration of unexpected shutdowns.

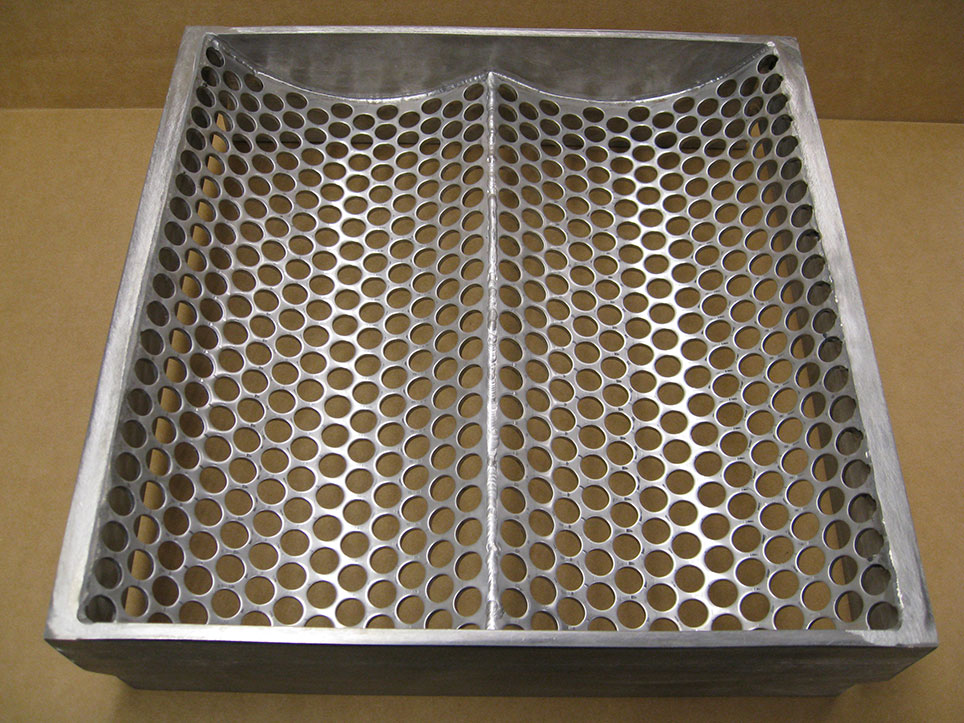

The Machines That Make It Happen

Having the right concept is one thing; having the right hardware is another. JERSEY CRUSHER offers a full inventory of equipment designed to handle the tough realities of industrial work. We provide the technology you need to move, feed, and sort your bulk solids efficiently.

Volumetric Feeders & Systems

Getting a consistent flow of material into your process is a game-changer. Our Volumetric Feeders are designed to dispense a reliable, repeatable volume of material over a set period. This means no more guesswork and no more “too much, too little” problems in your mix. Your accuracy skyrockets, and waste goes down.

Screw Conveyors

You need to move bulk materials from point A to point B cleanly and effectively. Our Screw Conveyors are the workhorses for the job. Enclosed and powerful, they transport everything from fine powders to granular materials without spillage or contamination, boosting your facility’s efficiency and cleanliness.

Serving Industries Across the Board

Every industry has its own unique challenges when it comes to handling solid materials. The goal is always a pure, consistent, and safe product. The screening and conveying technology we provide at JERSEY CRUSHER helps facilities like yours hit those goals daily.

Here is how different sectors benefit:

- Chemical: Achieve powder purity and uniform particle sizes for predictable chemical reactions and a high-quality finished compound.

- Fertilizing: Create uniform pellets and granules for even distribution in the field and a more effective product.

- Food: Sift and sort ingredients to remove foreign objects and guarantee product safety and consistency, from sugar to flour.

- Mineral: Separate valuable minerals by size and grade for more effective mineral processing and a higher yield.

- Pharmaceutical: Screen active ingredients and excipients for ultimate purity and precise particle sizing in a controlled environment.

- Sugar: Break up lumps and classify crystals by size to create a free-flowing, high-value product.

No matter your field, from food manufacturing to raw wood processing, controlling your material stream is key to success. JERSEY CRUSHER has the equipment to help you manage that stream from start to finish.

Build for Your Bottom Line

At the end of the day, new equipment has to improve your operation and pay for itself. Our industrial screeners are built for just that. By improving your workflow, you reduce wasted material, cut down on rejected batches, and protect your other machinery from damage. The advanced technology behind our equipment is designed to increase your operational efficiency so you can focus on growth.

More From Our Company

You’ve seen how JERSEY CRUSHER provides the industrial screening equipment to bring order and efficiency to your material stream. But that’s just part of what we offer to boost your facility’s productivity.

We have an entire lineup of industrial-grade machinery ready to go to work for you. The right equipment is waiting.

Order your Particle-izers, Lump Abradors, and more from JERSEY CRUSHER today.