Lump breakers are powerful machines that break down large, clumped materials into smaller, more manageable particles. They’re workhorses in industrial settings where materials tend to clump together due to moisture, pressure, or storage conditions. These machines come in various sizes and designs to tackle different materials like food products, chemicals, and minerals. You’ll find them quietly making production lines more productive across countless facilities.

The benefits of adding a lump breaker to your operation go well beyond just breaking things apart. Sure, they reduce downtime, prevent equipment jams, and boost your overall output. But there’s more to the story. While many facilities could mention dozens of ways these machines help them daily, these top 5 advantages make lump breakers essential equipment for any processing operation.

Number 5: Improved Material Flow and Reduced Production Bottlenecks

When materials clump together, they create bottlenecks in your production line. Imagine having a huge chunk of sugar or salt getting stuck in your conveyor system, bringing everything to a grinding halt. Frustrating, right? Lump breakers solve this problem by breaking down those troublesome chunks before they cause issues.

With a lump breaker in your processing line, materials flow smoothly through the system. This means fewer jams, less downtime, and a more consistent production process. Your workers won’t need to stop operations to clear blockages manually—a task that wastes time and creates safety risks.

Number 4: Consistent Particle Size for Better Quality Control

Getting uniform particle size directly impacts your product quality. When materials vary wildly in size, they can behave unpredictably during processing, affecting everything from mixing to reaction times.

Lump breakers deliver reliable particle reduction that gives you more control over your end product. For food processing operations, this means better texture and cooking properties. In chemical manufacturing, it means more predictable reactions and better product performance.

The steel construction of quality lump breakers helps maintain this consistency over thousands of operating hours. JERSEY CRUSHER offers machines that are built with precision tolerances that deliver dependable results batch after batch.

Number 3: Significant Energy Savings Across Your Operation

Running equipment with clumped materials wastes energy. Why? Because your machines work harder to process inconsistent materials, drawing more power and wearing out faster.

A lump breaker tackles this issue at the source. By breaking down materials before they enter your main processing equipment, you reduce the strain on downstream machines. Your grinders, mixers, and other equipment can operate at peak efficiency rather than struggling with oversized chunks.

Number 2: Extended Equipment Life and Reduced Maintenance Costs

Nothing drains your maintenance budget faster than equipment damage from material jams. When chunky materials force their way through machinery not designed to handle them, you get wear, heat damage, and premature equipment failure.

Lump breakers protect your expensive processing equipment. By dealing with difficult materials first, they prevent that damage from occurring. Consider what happens in industries like powder processing—without proper size reduction, mixers and packaging equipment face constant strain.

Number 1: Versatility Across Multiple Materials and Applications

Arguably the biggest advantage of modern lump breakers is their incredible versatility. The same machine that processes pet food ingredients today could handle chemical compounds tomorrow. This flexibility makes lump breakers uniquely valuable in multi-product facilities.

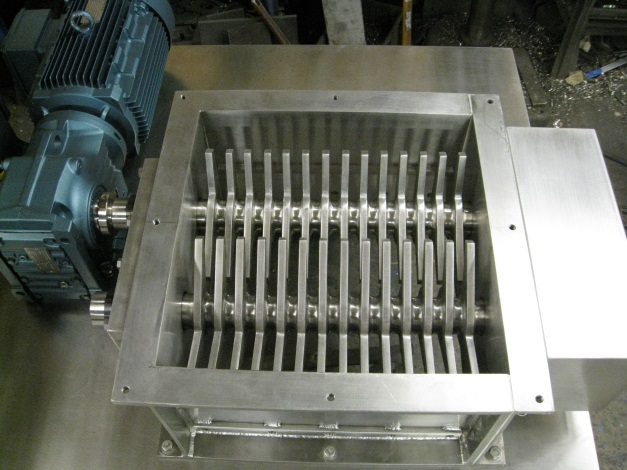

Modern lump breakers handle wet and dry materials, can process items with high moisture content, and work with everything from soft agglomerates to harder materials. This versatility comes from thoughtful engineering—different rotor designs, screen configurations, and drive options let you tailor the machine to your specific needs. This is especially beneficial as industries start to merge and production varies across organizations. In order to merge your company with others, you must have quality materials that get the job done in many different ways. Lump breakers can do this and more.

Get Results with JERSEY CRUSHER

You can solve your toughest material handling challenges with our state-of-the-art LUMPBUSTER® line that brings tremendous value to your company. Our range of models covers applications from light-duty to the most demanding industrial environments:

- Model 1212

- Model 1515

- Model 2020 (And its sanitary stainless steel variant.)

- Model 2028

- Model 2424

From sugar to salt, mining waste to chemical compounds, our machines deliver the particle size reduction you need for maximum productivity. With options in food-grade stainless steel or industrial carbon steel, you’ll get equipment that fits your exact requirements. Give us a call today.