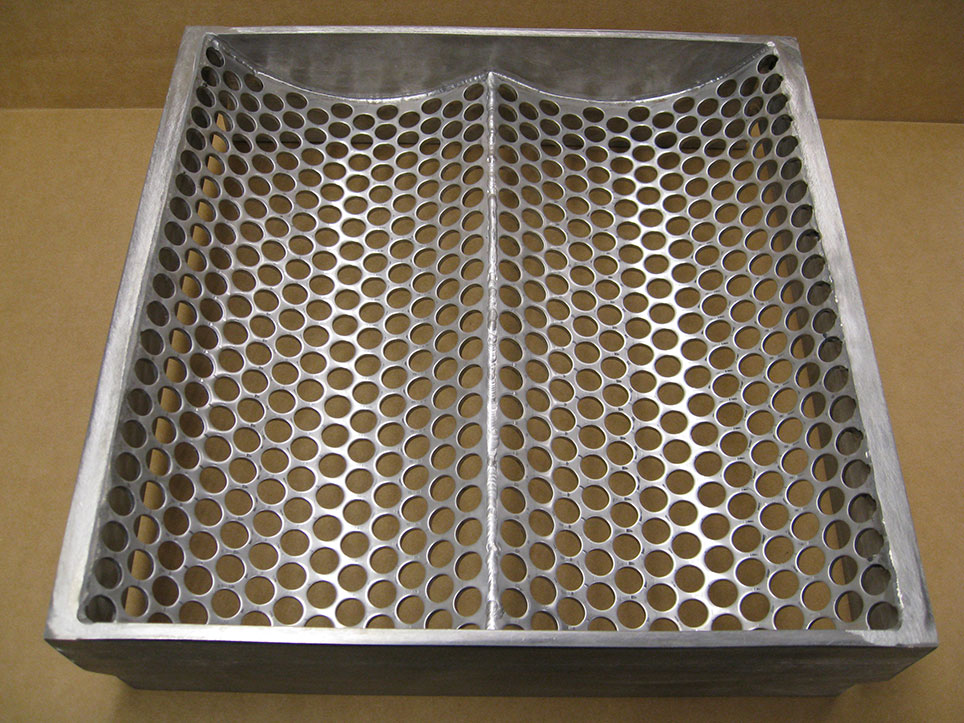

Sizing Screen

Every lump breaker relies on a critical component to function optimally: the sizing screen. Without it, managing particle size distribution and achieving consistent results in your production process becomes a frustrating challenge. Sizing screens determine the efficiency and accuracy of material size reduction, making them indispensable for maintaining minimal fines and ensuring higher capacity for your machines. JERSEY CRUSHER, a leader in lump breaker solutions, offers this fantastic sizing screen designed to enhance your equipment’s performance across a range of industries.

Features of Our Sizing Screen

JERSEY CRUSHER designs sizing screens that strike the perfect balance between durability and performance. Crafted with precision, our screen comes with customizable round holes or slots, enabling you to match specific application needs. The open area of each screen is engineered to optimize throughput while maintaining consistent bulk density and minimal wear. These screens function like a fine-tuned “cheese grater,” allowing for versatile size reduction across fibrous products, friable products, and bulk solids. If you’re processing fine powders or coarse granules, a thicker screen provides the ruggedness required for demanding production environments. This attention to detail translates to improved efficiency and a longer equipment lifespan. Each screen is built to withstand the rigors of heavy use. Our sizing screens help create consistent results, ensuring a smoother workflow with minimal interruptions.What Is a Sizing Screen and Why Lump Breakers Need Them

A lump breaker is vital for reducing the size of bulk solids, ensuring a consistent material flow throughout the production process. It uses rotating blades to crush and grind materials against the sizing screen, breaking lumps into manageable particles. A sizing screen elevates your lump breaker’s capabilities, transforming it into a precision tool that efficiently manages a range of bulk solids. The lump breaker’s design allows for versatility, enabling you to target specific size-reduction requirements. A lump breaker sizing screen serves as your lump breaker’s control panel, dictating the material output’s size and shape. These screens, placed strategically inside the mill or breaker, sift material through pre-defined holes or slots, regulating particle size distribution.Read More

Key Benefits of Sizing Screens:

- Achieve precise particle size distribution for diverse materials.

- Maintain consistent bulk density for downstream processes.

- Improve efficiency by minimizing fines and optimizing throughput.

Industries That Benefit from Our Sizing Screens

Mineral Processing

In mineral processing, maintaining consistent particle size distribution is critical. Our screens help manage bulk solids like ores and minerals, ensuring uniform size reduction that optimizes downstream milling operations.Chemical Industry

For the chemical industry, achieving minimal fines is crucial for product consistency and safety. The durable design of our sizing screens withstands harsh conditions, enabling efficient processing of powders, granules, and fibrous products.Food Industry

Food production relies on precision. Our sizing screens reduce ingredients to the ideal particle size. From grains to spices, these screens support higher capacity and ensure quality control. In an industry where this is common, they can be used for larger or smaller particles.Sizing Screens for All Our Lump Breaker Machinery

Your sizing screen is nothing without a quality lump breaker. So get yours today! Pair this sizing screen with one of our popular lump breaker machines, including our:Is Your Lump Breaker Operating at Full Potential?

Do you know the value a sizing screen brings to your operation? Without one, your lump breaker isn’t living up to its full potential. JERSEY CRUSHER sizing screen is engineered to suit a variety of needs, offering a durable, versatile, and efficient solution for size reduction. Create better outcomes with a screen designed for your industry. Get yours today!