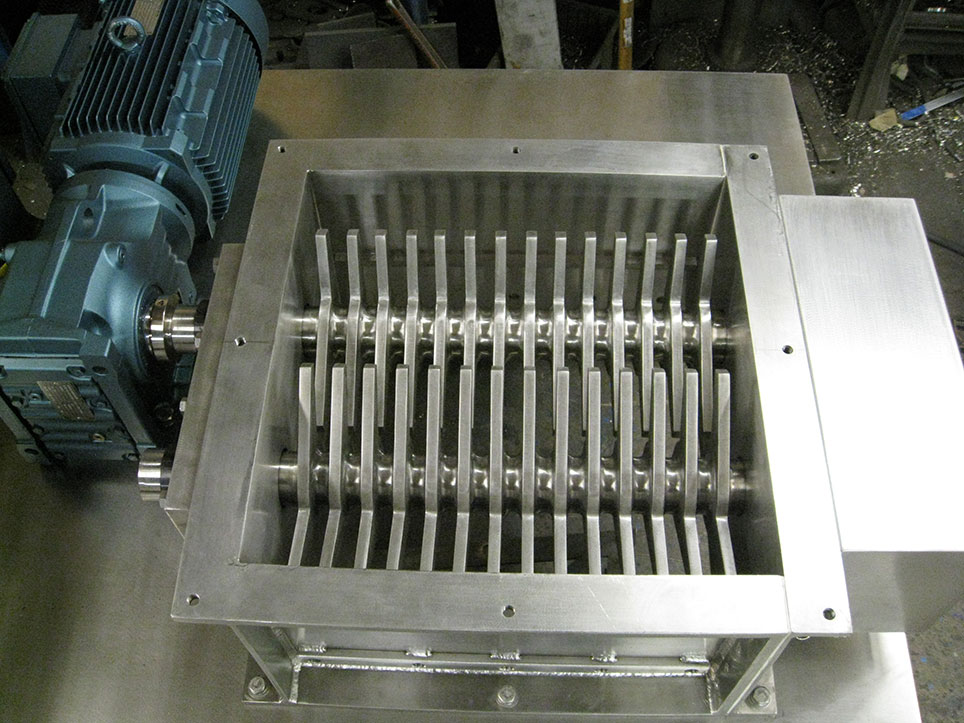

Model 2020 Sanitary Stainless Steel

Read More

This advanced system is just a small part of our portfolio of lump breaking technology, setting new benchmarks for material processing efficiency and offering unprecedented control over particle size reduction. Your operation gains a powerful ally in maintaining product consistency while maximizing throughput rates. The Model 2020’s innovative design emerged from decades of field experience and engineering refinement. Experience it for yourself today with JERSEY CRUSHER.Advanced Features of Our Model 2020 Lumpbuster

Your production demands equipment that delivers consistent results. The Model 2020’s cutting-edge design incorporates precise engineering that sets new standards for breaking down large lumps and challenging materials. The direct drive system eliminates maintenance-heavy belt drives while maximizing power transfer efficiency. Teams appreciate the tool-free access that simplifies cleaning and maintenance. The reinforced shaft assembly maintains strict tolerances even under heavy loads, while the precision-machined rotors efficiently process your most demanding materials. These core features play a vital role in maintaining the smooth operation and consistent output quality that your process requires.

How JERSEY CRUSHER’s Advanced Lump Breaking Technology Puts You Ahead of the Competition

Modern processing operations MUST meet increasing demands for uniform product consistency. You can count on us to do so. The Model 2020 Lumpbuster is just one of the tools that have helped companies transform how they handle difficult materials. By eliminating troublesome clumps that slow production, you’ll experience dramatic improvements in downstream processing efficiency, reduced equipment wear, and more consistent product quality.

The system’s ability to break down oversized materials into controlled particle sizes optimizes flow characteristics while preventing unwanted agglomeration. The innovative design also reduces power consumption compared to traditional size reduction methods. This all combines to help you achieve a smoother operation, reduced downtime, and superior end products that exceed quality standards.

Premium Stainless Steel Construction

When processing sensitive materials, the construction materials you select form the foundation of product integrity. The Model 2020’s stainless steel build provides superior corrosion resistance while maintaining strict sanitary standards. This premium material choice prevents contamination risks and simplifies cleaning procedures.

The non-porous surface resists bacterial growth and product accumulation, making it ideal for food, pharmaceutical, and chemical applications. The strength and resistance of stainless steel construction also extend equipment life while reducing maintenance requirements. When you choose a lumpbuster made of this superior material choice, you will see long-term value through consistent performance and reduced total cost of ownership.

Versatile Applications for Our Model 2020

Food Processing

Break down frozen meat blocks, deagglomerate sugar and salt, process dried fruits, and reduce spice clumps to manageable sizes. The sanitary design meets strict food safety requirements, and the system’s gentle yet effective size reduction preserves critical product characteristics while maintaining throughput rates. Special considerations for dairy products include easy-clean features that support frequent product changeovers. When processing temperature-sensitive materials like chocolate or butter, the system’s controlled operation prevents unwanted melting or texture changes.

Chemical Processing

Efficiently process filter cakes, break down chemical agglomerates, and reduce raw material particle sizes. The corrosion-resistant construction handles aggressive materials safely. The Model 2020’s sealed design prevents dust emissions while processing dry chemicals, protecting both operators and the environment. Your chemical processing operations benefit from the system’s ability to handle varying feed rates and material consistencies. If you’re processing hygroscopic materials that tend to clump or break down filter cakes with varying moisture content, the Model 2020 maintains consistent output quality.

Pharmaceutical Manufacturing

Deagglomerate active ingredients, size reduction of excipients, and process dried materials within strict regulatory guidelines. The Model 2020’s documentation package supports validation requirements, including IQ/OQ protocols and material certifications. The system’s clean-in-place compatibility reduces cross-contamination risks between batches. Pharmaceutical manufacturers particularly value the system’s ability to maintain precise particle size distributions for proper drug formulation.

Explore Our Complete Size Reduction Solutions

Beyond the Model 2020, JERSEY CRUSHER offers an extensive range of products designed for your specific processing challenges. Our product line includes custom feeders/material handling systems and lump breakers like our Model 1515 for unique applications. Contact our team to discover how these additional solutions can optimize your entire process flow. We sell integrated systems that revolutionize material processing efficiency across multiple industries.

Your Nationwide Source for Superior Size Reduction

The Model 2020 Lumpbuster represents JERSEY CRUSHER’s commitment to advancing material processing technology. From its premium stainless steel construction to its powerful performance capabilities, this advanced lump breaker delivers the results your operation demands. With nationwide service and support, we stand ready to help you achieve new levels of processing efficiency.

Order your Model 2020 today!