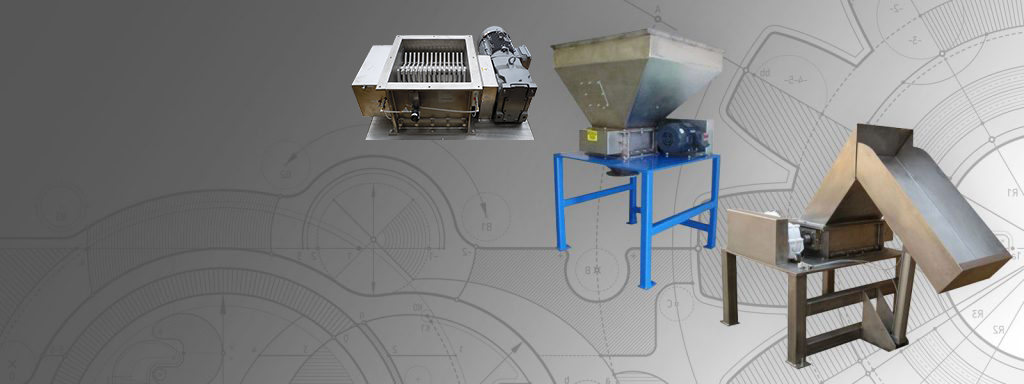

So, what is a lump breaker also industrial crusher? The main function of the Lump Breakers and Stainless Steel Crushers is to grind nougat material that has been formed. For example, by hydration in silos or hoppers. Lump breakers can be located horizontally or vertically, depending on the need, using them at the discharge point normally ahead of the discharge equipment, for example, flow control valves.

How do Lump Breakers work?

Lump Breakers with breaker arms located radially move by an axis attracts the nougats or lumps against the grate where they are crushed and broken. The safe operation of the Stainless Steel Crusher is ensured by an overload protection system and a reversal system. All of this is done automatically through an integrated control panel.

Lump Breakers system allows to break the lumps that form in the materials during the production process.

What is a Lump Breaker system

The Lump Breaker system is particularly suitable for hygroscopic materials or packaging. And due to its versatility, it can be used in all industrial sectors. It is distinguished by its self-cleaning “design” with minimal dimensions. It can be mounted even within existing systems or systems for emptying (bags, drums and Big-Bag) or the performance of filter driers, centrifuges, mixers and machines.

Lump Breakers: a process in general.

The lump breaker system comprises a central Stainless Steel Crusher body with a circular cross-section where the shaft with the blades for crushing the product and a contrasting grid are housed. Two flanges are connected to the central body of the lump breaker system. It is an upper one for the input of the raw product and a lower one for the evacuation of the crushed product.

The breaking of the lumps is carried out through the rotation of the special blades within a contrasting grid whose movement is imparted through a gear motor. For safety reasons, the Lump Breaker system is equipped with inductive sensors that allow the machine to start only when the mounting configuration is correct.

Lump Break Feed Valves: No clogging, even with hardened material

The Lump Break Feed Valve allows for safe and smooth segregation of bulk materials that tend to pack and clump during production and / or storage. Its design favors soft crushing even with hardened material under a column of medium-high material.

Technical Specifications

Description:

Lump Breaker device consists of a solid cylindrical body with inlet and outlet flange. It is an integrated crushing tool driven by a later ally located electric motor, and a rigid screen. To fit the required particle size, the blades and screen are easily removable to fit according to the desired characteristics of the material.

Function:

The lump break feed valve is fed with agglomerated solids that are discharged through the outlet for further processing after being crushed. The Lump Breaker is the ideal solution for breaking snowball-like materials. It is particularly suitable for hygroscopic materials. The lump break feed valve can be installed in loading and/or unloading pipelines to empty or fill drums, containers or screw conveyors.

Characteristics:

• Cylindrical connection

• Single-axis configuration

• Replaceable blades

• Easy to disassemble and clean

Advantage:

• Compact design for easy maintenance

• Segregation without particle degradation

• Improved material quality

• Improved material flow

• Higher energy efficiency

• Profitable operation

• Connexion eye knot

What can an Industrial Crusher do?

Industrial Crusher is a compact design crusher, designed respecting a modular structure, which allows the customer to also use it as a pre-crusher by connecting it. For example, to a vibrating screen capable of collecting eventual oversized particles, or to a calibrator, thus guaranteeing perfect precision in the selection of materials.

Industrial Crusher is the right crusher in particularly delicate and complex production processes, guaranteeing the safety of the entire plant, people and the end product.

Jersey Crusher’s catalogue:

Jersey Crusher Lump Breakers and Stainless Steel Crushers are manufactured according to the most up-to-date regulations, laws and guidelines on the highest standards of sanitation, safety and cleanliness.

Stainless Steel Crushers are designed so that each component fits perfectly together, creating a gap-free match, and preventing product from being stored inside. Thus, avoiding product cross-contamination.

From metal powder to delivery of the final product, we track and document all events associated with each part and component to offer complete traceability of all our products. This is especially important in the pharmaceutical and food industry, to ensure the quality of production lines and track possible problems to intervene and quickly solve related problems.